|

MAKING

A PAPER PATTERN MAKING

A PAPER PATTERN

- Perhaps the easiest way to lay sheet vinyl is by using a paper pattern of the floor.

Installation kits are available that contain paper, guides and instructions. You can make

a pattern with brown kraft paper, a pair of scissors, straightedge, utility knife and some

masking tape.

- Begin by laying the paper down along the longest wall with the fewest obstructions. If

you cut your flooring the exact size of the room, it is likely to roll up or buckle. Allow

about an eight of an inch between the pattern and the wall (Fig. 7).

- Keep adding paper until you reach the opposite wall. Use masking tape to tape the paper

together. Cut small diamond shapes about every two to four feet in all directions on your

pattern. Place masking tape over these cutouts to hold the pattern in place.

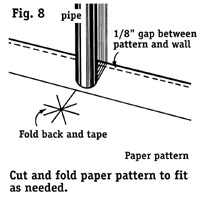

- Keep the paper as smooth as possible. Use plenty of tape along the edges of the paper to

hold the pattern together. Use small sheets of paper to fit around pipes, toilets,

cabinets, appliances and heating vents. Cut and fold these smaller pieces to fit. Then

tape them to the pattern (Fig. 8). If you make an opening too large, use tape and paper to

correct the size.

- After you have completed the pattern, use a felt marker to mark the side of the pattern.

- Carefully roll or fold the pattern. Take it to a large clean floor area. A garage floor

that has been thoroughly swept works well.

- Most sheet flooring today is sold in 12 foot widths. If you have a room that is larger

than 12 feet in length and width, you will need to make a seam. Plan for seams to be in

low traffic areas if possible. Use the pattern of your flooring to help hide the seam. For

example, if your pattern has heavy lines, such as sides of boards or grout lines, make

your seam along these lines.

- To make the seam, lay the larger piece of flooring down first, right side up. Then place

the smaller piece, right side up also, so the two pieces overlap by at least an inch. Most

importantly, lay them so the pattern on both pieces match (Fig. 9). Tape the two pieces

together.

- Use a straightedge and sharp utility knife to cut through both layers of flooring.

Depending on where you are working, you may want to lay pieces of cardboard under the

flooring so you don't damage the floor. Remove the two trimmed edges. Carefully put the

seam together again and retape the seam.

- After the seam is made, you are ready to cut the flooring. Place the pattern, right side

up, on top of the flooring. If you haven't already done so, remove the tape covering the

small diamonds and replace it with new tape. Be sure the pattern is laying so that the

seam is where you planned and that it is laying flat.

- To cut the flooring you have two options. You can trace the pattern onto the flooring

using a straightedge and a marker. And then cut it with heavy shears or snips. Or you can

use a utility knife and straightedge and cut around the pattern. Either way, be very

careful.

- After you have finished cutting the flooring, carefully roll it. The way you roll it can

make the job easier. For example, rolling it toward an edge that goes next to a cabinet

makes fitting it under the toe plate easier. Also, remember the length. If you have to go

around any sharp corners, roll it so it is as short as possible.

|

MAKING

A PAPER PATTERN

MAKING

A PAPER PATTERN

LAYING ROLL GOODS

LAYING ROLL GOODS