|

FIG.

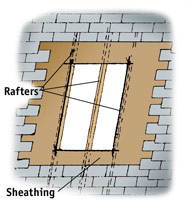

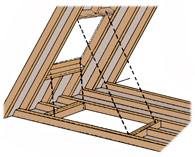

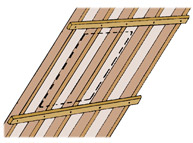

4 -A skylight framing assembly consists of the roof opening, the light

shaft and the ceiling opening.

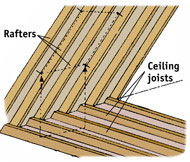

FIG. 5 - Locate the corners of the ceiling opening closest to the outside wall, then use a plumb bob to find the location of the roof opening.

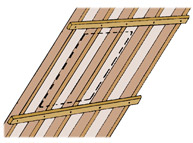

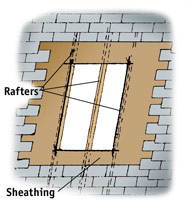

FIG. 6 - Drive nails

up through the roof to mark the corners of the rough opening, then strip away the shingles

and cut the sheathing with a circular saw.

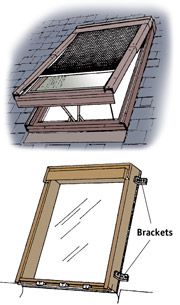

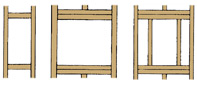

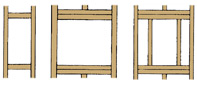

FIG. 7 - If your skylight

will fit between existing rafters, you'll only need a single header (left).

If you have to cut a rafter, use double headers (center). If the skylight

will be placed in line with a rafter, use double headers and fill in the

opening with trimmer rafters (right).

FIG. 8 - Before cutting the rafter, nail temporary supports across the adjoining rafters to keep the roof from sagging.

|

FRAMING THE ROUGH OPENING

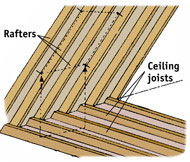

- A skylight framing assembly consists of three parts (Fig. 4):

- The roof opening is framed with headers–framing lumber run horizontally across the opening, securely nailed to the rafters to support the structure. Headers are cut from lumber the same size as the rafters.

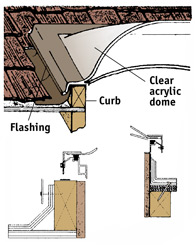

- A curb-mounted skylight also requires a framed curb, typically 2x6s but usually specified by the skylight manufacturer (the frame has to project far enough to accommodate the flashing). The curb is set on the roof sheathing around the perimeter of the opening, and the skylight is set on the curb.

- The ceiling opening is framed in the same way as the roof opening–headers are nailed between the ceiling joists to support the existing framing. Ceiling headers should be the same size as the ceiling joists.

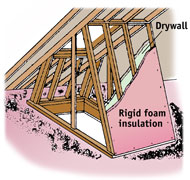

- The light shaft is the framing that connects the

roof opening with the ceiling opening. It is typically framed with

2x4s, insulated like any interior wall and finished on the inside

with drywall or other material. The light shaft may be vertical or

flared–wider at the bottom than the top. A flared light shaft

is a little more difficult to frame but will admit more light.

- To frame the opening for a skylight, first decide on the approximate location of your skylight. It should be roughly centered in the room.

- Next, locate the ceiling joists, then realign the opening so it fits between the joists. Depending on the size of your skylight, you may or may not have to cut the ceiling joists and rafters; many skylights are made to fit between 16" or 24" on center joists and rafters without removing any framing.

- Mark the two corners of the ceiling opening closest to the outside wall. Take care to make sure the points are parallel to the wall. The width of the ceiling opening should match the rough opening width of the skylight (specified by the manufacturer). The length will vary, depending on the type of light shaft you want.

- Drill small holes through the ceiling at your marks

and push two pieces of stiff wire up into the attic so you can easily

spot the location from above.

- Go up to the attic; if possible, bring a 2' by 4'

piece of plywood with you to lay across the ceiling joists so you

won't accidentally put a foot through the ceiling. Locate your corners

and clear the insulation away from the area. If you have to reroute

electrical wiring, always turn the power off first and double check

by testing a fixture on that circuit with an electrical tester.

- Use a plumb bob to locate the two points on the underside of the roof that are directly above the lower corners of the ceiling opening. Mark those points on the roof (Fig. 5). Double check to make sure they match the correct rough opening width, then measure up the underside of the roof the specified rough opening length. Drive four nails up through the roof to mark the corners of your rough opening.

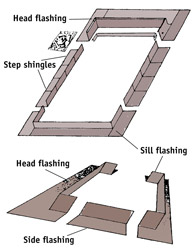

- Go up to the roof and remove the shingles from around the opening, far enough to allow room to install the flashing. Snap chalk lines between the nails, then cut away the roofing felt with a utility knife.

- Set your circular saw so the blade depth is slightly more than the thickness of the roof sheathing, then cut away the sheathing and remove it (Fig. 6).

- How you frame the opening depends on the size and position of your skylight. If the skylight will fit between two existing rafters without cutting, simply cut two headers to fit between the rafters (they should be the same material as the rafters, typically 2x6s) and nail them in place with 16d common nails, flush with the cut edges of the sheathing (Fig. 7).

- If you have to cut a rafter, framing is a little more complex. First, nail two 2x4s across the rafters to provide temporary support (Fig. 8). The 2x4s should be long enough to reach at least two rafters on each side of the one that will be cut.

- Then use a reciprocating saw to cut the rafter out

of the opening 3" back from the edge of the sheathing on each

side. Cut four headers to span the distance between the uncut rafters

on each side of the opening. Nail the first pair flush against the

two ends of the cut rafter. Use three 16d common nails through the

existing rafters into the headers on each end and three more nails

through the header into the end of the cut rafter.

- Then nail the second pair of headers in place. Use

16d nails to nail through the existing rafters into the ends of the

header and a pair of 8d nails every 16" to nail the two headers

together.

|