|

|

|

|

|

|

|

|

|

|

GENERAL CONSIDERATIONS

|

MOUNTING THE

CEILING FAN MOUNTING THE

CEILING FAN

|

|

ASSEMBLY ASSEMBLY

|

|

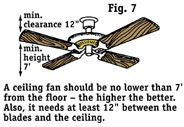

HEIGHT BENEATH

BLADES HEIGHT BENEATH

BLADES

|

|

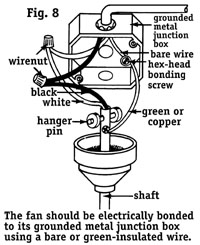

MOUNTING THE FAN TO THE BOX

|

|

PROBLEM HANGING PROBLEM HANGING

|

|

SWAG KIT USE SWAG KIT USE

|

TOOL AND MATERIAL CHECKLIST  ELECTRICAL SAFETY

ELECTRICAL SAFETY

Ceiling Fan

Mounting Kit

Swag Kit

Lock Washers

Low-Ceiling Mount

Angled-Ceiling Mount

Patented Support Unit

4" x 1 1/2" Octagon Electrical Box

Cable, Switch/Outlet Box, Switch, Box Connectors,

Wirenuts, Switch Cover, Bonding Screw, Staples

Neon Test Light

No. 2 Phillips Screwdriver

Claw Hammer

3/16" Slotted Screwdriver

Speed Controller

Pliers

Wallboard or Compass Saw

Soft Cloth

Stud Locator

Ladder

Electrician's Pliers

Wire-Stripper

Cable-Ripper

Surface-Wiring System

Check your state and local codes before starting any project. Follow all safety precautions. Information in this on-line brochure has been furnished by the National Retail Hardware Association. Every effort has been made to ensure accuracy and safety. Neither the NRHA nor the retailer can be held responsible for damages or injuries resulting from the use of the information in this document.